High Tg PCB: Why It Matters for High-Temperature and High-Reliability Electronics

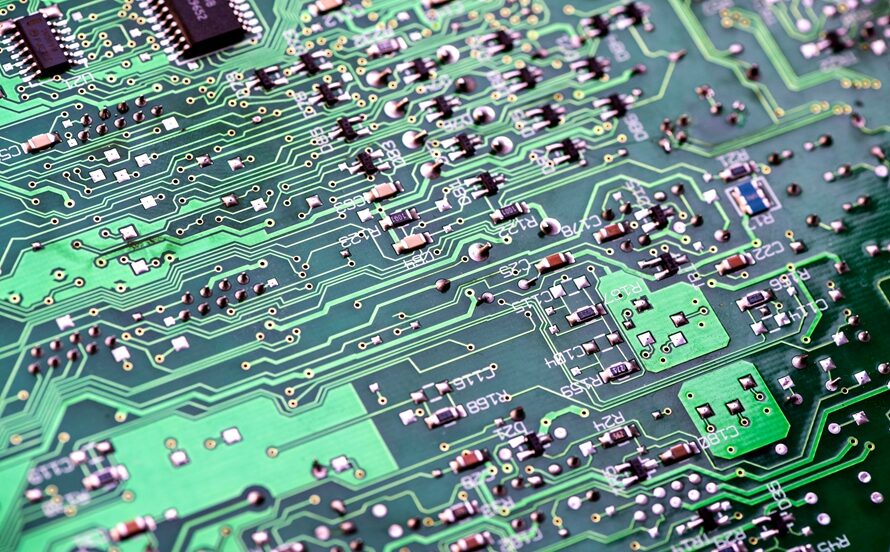

As electronic devices become more powerful and compact, heat management has become one of the most critical challenges in PCB design. From industrial automation systems to automotive control modules, modern circuits must withstand elevated operating temperatures without compromising performance. This is where a High Tg PCB plays a vital role.

If you are developing products exposed to thermal stress, partnering with an experienced High Tg PCB manufacturer can significantly improve reliability and long-term durability. In this guide, we will explore what High Tg means, why it matters, its advantages over standard materials, and how to choose the right manufacturing partner.

What Is a High Tg PCB?

The term “Tg” stands for glass transition temperature. It refers to the temperature at which the PCB substrate material transitions from a rigid, glassy state to a softer, rubber-like state. When the material exceeds this temperature, its mechanical strength and dimensional stability decrease.

A High Tg PCB uses laminate materials with a higher glass transition temperature compared to standard FR-4 materials. While regular FR-4 boards typically have a Tg around 130°C–140°C, High Tg materials often exceed 170°C and can go beyond 180°C or even 200°C.

This higher threshold ensures that the board maintains structural integrity and electrical stability under high-temperature conditions, making it ideal for demanding applications.

Why Tg Is Critical in PCB Design

Understanding Tg is essential for engineers designing circuits that generate or experience heat.

When a PCB operates near or above its Tg, several issues can occur. The board may expand excessively, causing misalignment between layers. Vias and plated holes may experience stress, leading to cracks or reliability failures. Solder joints can also weaken due to repeated thermal cycling.

A High Tg PCB minimizes these risks by maintaining mechanical stability even under elevated temperatures. This improves the board’s resistance to delamination, warpage, and thermal stress.

In applications involving high current loads, power electronics, or continuous operation in hot environments, High Tg materials are often not just beneficial but necessary.

Advantages of High Tg PCB

One of the main advantages of a High Tg PCB is improved thermal resistance. The board can withstand higher soldering temperatures and repeated reflow cycles without degradation.

Another important benefit is better dimensional stability. When exposed to heat, low-Tg materials tend to expand more significantly. High Tg materials maintain their shape and alignment, which is crucial in multilayer and high-density interconnect designs.

High Tg PCBs also offer enhanced mechanical strength. This reduces the risk of cracking during assembly or operation, particularly in environments subject to vibration or thermal cycling.

In addition, these boards provide improved reliability in lead-free soldering processes. Lead-free solder requires higher reflow temperatures, which can stress standard PCB materials. High Tg substrates are better suited for these modern assembly standards.

Applications of High Tg PCB

High Tg PCBs are widely used in industries where heat and reliability are major concerns.

In automotive electronics, engine control units, transmission modules, and battery management systems operate in high-temperature environments. High Tg materials ensure consistent performance despite constant exposure to heat.

Industrial equipment, including motor drives, power supplies, and control systems, also relies on High Tg PCBs to handle heavy electrical loads and thermal stress.

Telecommunication infrastructure, such as base stations and network equipment, often generates significant heat during operation. Using High Tg substrates enhances system stability and longevity.

In aerospace and defense applications, reliability under extreme environmental conditions is critical. High Tg PCBs provide the durability needed for mission-critical electronics.

Even in consumer electronics, high-performance devices such as gaming systems and power adapters may benefit from High Tg materials to prevent overheating-related failures.

High Tg PCB vs. Standard FR-4

Although standard FR-4 is suitable for many general-purpose applications, it may not perform adequately under high-temperature conditions.

A High Tg PCB offers superior heat resistance, reduced thermal expansion, and improved mechanical reliability. In contrast, standard FR-4 materials may experience delamination, cracking, or electrical instability when exposed to prolonged heat.

While High Tg materials are generally more expensive than standard laminates, the additional cost is justified in applications where failure is not an option. Investing in High Tg technology reduces long-term maintenance, warranty claims, and product recalls.

For high-power, multilayer, or thermally demanding designs, High Tg PCBs are often the preferred choice.

Manufacturing Considerations for High Tg PCB

Producing a High Tg PCB requires precise material handling and process control.

The lamination process must be carefully managed to ensure proper bonding between layers. Since High Tg materials often have different thermal expansion characteristics, manufacturers must optimize temperature profiles and pressure settings.

Drilling and plating processes also require expertise. Proper hole wall quality is essential to prevent via failures during thermal cycling.

In addition, strict quality control procedures such as thermal stress testing, microsection analysis, and electrical testing are necessary to verify performance.

Working with an experienced High Tg PCB manufacturer ensures that these processes are carefully managed and that the final product meets industry standards.

Choosing the Right High Tg PCB Manufacturer

Selecting the right High Tg PCB manufacturer is a critical step in ensuring product reliability.

First, evaluate the manufacturer’s experience with high-temperature laminate materials. Not all PCB suppliers specialize in High Tg production, and improper processing can compromise performance.

Second, review their quality certifications and compliance with IPC standards. Certifications such as ISO 9001 demonstrate a commitment to consistent quality control.

Third, consider their engineering support capabilities. A reliable manufacturer will assist with stack-up design, material selection, and thermal management optimization.

Production capacity is also important. Whether you need prototypes, low-volume production, or high-volume manufacturing, your chosen partner should be able to scale efficiently.

Finally, assess their testing and inspection capabilities. Advanced equipment for impedance testing, thermal cycling, and reliability analysis ensures your boards meet strict performance requirements.

Cost vs. Long-Term Reliability

Although High Tg PCBs may have a higher initial cost compared to standard materials, they often provide significant long-term savings.

Boards that fail due to thermal stress can result in expensive repairs, downtime, and damage to brand reputation. By choosing High Tg materials from a reputable High Tg PCB manufacturer, companies reduce the risk of premature failure and extend product lifespan.

In industries such as automotive, aerospace, and industrial automation, the cost of failure far exceeds the cost difference between standard and High Tg materials.

Conclusion

A High Tg PCB is an essential solution for electronic systems operating in high-temperature or high-reliability environments. With superior thermal resistance, dimensional stability, and mechanical strength, High Tg materials significantly improve PCB performance and durability.

However, the quality of the final board depends heavily on manufacturing expertise. Partnering with a professional High Tg PCB manufacturer ensures precise processing, strict quality control, and reliable results.

If your application involves high power, thermal stress, or demanding environmental conditions, choosing a trusted manufacturer for your High Tg PCB requirements will provide the performance, reliability, and long-term value your products need to succeed in competitive markets.

Post Comment