Unleashing the Potential of Ceramics with Sodiceram

Ceramics have long been celebrated for his or her strength, heat resistance, and enduring visible appeal. Traditional ceramics, however, frequently come upon obstacles in important regions such as porosity, structural integrity, and adaptability, especially beneath excessive situations. This is in which Sodiceram steps in—a current, sodium-more desirable ceramic designed to conquer those demanding situations.

By integrating sodium-based compounds directly into the ceramic framework, Sodiceram supplies first rate overall performance improvements without compromising aesthetic high-quality. This modern technique enhances durability, reduces vulnerability to cracking, and permits for more versatile layout possibilities. Architects, industrial engineers, and indoors designers can now explore innovative applications starting from fashionable residential surfaces to robust industrial additives and dynamic architectural façades.

Beyond its practical benefits, Sodiceram additionally aligns with sustainability goals. Its stronger toughness reduces the want for a common substitute, at the same time as its adaptive houses decrease cloth waste all through manufacturing. In essence, Sodiceram represents a harmonious mixture of technology, layout, and environmental duty—ushering in a brand new generation where ceramic substances aren’t just useful, but additionally remarkably versatile and visually placing.

Sodiceram: The Next-Generation Ceramic Revolution

Sodiceram is an innovative ceramic cloth designed with advanced sodium-primarily based compounds to enhance sturdiness, minimize porosity, and supply visually lovely surfaces. Unlike traditional ceramics or porcelain, sodiceram utilizes specialised flux chemistry to the microscopic degree, resulting in a material that plays especially well below traumatic conditions.

The term “Sodiceram” is derived from sodium-infused ceramic, highlighting its core technological development. By incorporating sodium oxides or sodium feldspar into the ceramic aggregate, manufacturers can increase the formation of the glassy phase inside the material. This procedure produces denser, more robust structures even as keeping specific manage over thermal growth. The result is a ceramic surface that isn’t always most effective, more potent but additionally immune to cracking, wear, and environmental stressors—regions where traditional ceramics often fall quickly.

The development of sodiceram originated at the intersection of contemporary ceramic technological know-how and modern architectural requirements. Architects and architects more and more demanded substances that blended structural electricity with aesthetic versatility. Researchers discovered that sodium, performing as a flux, may want to considerably enhance vitrification—the technique of transforming a material into a pitcher-like country—resulting in smoother, tougher surfaces. These laboratory innovations paved the way for sodiceram’s industrial use, making it a famous desire for excessive-overall performance applications such as flooring, wall cladding, counter tops, and different interior or outside design elements.

In precision, sodiceram represents a fusion of medical precision and design innovation, supplying a ceramic solution that is each incredibly long lasting and visually appealing. Its precise sodium-primarily based components unite it aside from conventional ceramics, assembling the evolving demands of contemporary structure and excessive-site visitors environments.

See also “Fascisterne: Tracing Its Ideological Impact Through Time“

Understanding the Name “Sodiceram”

The call “Sodiceram” is derived from the aggregate of sodium (sodi‑) and ceramics (‑ceram), reflecting its specific medical formula. Sodium plays a pivotal position in the material’s production, appearing as a flux that enables melting and glass formation throughout firing. This vital feature units sodiceram other than traditional ceramic substances consisting of porcelain or stoneware. Beyond its technical significance, the name additionally positions the cloth strategically within the layout and architectural markets, emphasizing both innovation and aesthetic versatility.

How Sodiceram Stands Out from Traditional Ceramics

While conventional ceramics in most cases rely on feldspar and kaolin clays to reap vitrification, they regularly retain a higher degree of porosity, commonly ranging from 1% to a few%. In assessment, sodiceram achieves terrific density with porosity degrees at or below 0.5%. This low porosity translates into superior water resistance, decreased absorption, and more desirable durability below freeze-thaw cycles, making it ideal for both indoor and outside applications.

From a mechanical attitude, sodiceram well-known shows remarkable energy, with flexural resistance exceeding 40 MPa—well above the everyday range of standard porcelain. Its superior components additionally lets in for diverse aesthetic finishes, accommodating the entirety from matte, industrial-style surfaces to sleek, decorative designs, all without compromising structural integrity. This mixture of durability, versatility, and beauty makes sodiceram a preferred choice for cutting-edge architectural and indoors packages.

The Material Science Behind Sodiceram

Sodiceram represents a significant advancement in modern-day ceramic engineering, combining scientific precision with practical performance. Its innovation lies in the strategic use of sodium-based compounds inside the ceramic frame, a way that optimizes vitrification at the same time as minimizing micro-cracks and residual porosity. This layout is rooted in superior ideas of flux chemistry, glass-ceramic formation, and controlled thermal expansion, allowing sodiceram to outperform conventional ceramics in each durability and aesthetic versatility.

Role of Sodium Compounds as Flux and Glass Former

Sodium performs a crucial role in lowering the melting factor of silica and alumina, vital components of the ceramic matrix. By appearing as a flux, sodium promotes liquid-segment sintering, allowing the ceramic grains to densify more efficiently at lower firing temperatures. This no longer best reduces power intake however additionally achieves tighter grain packing, improving structural concord and developing a far better final product.

How Sodiceram Achieves Exceptional Density and Low Porosity

The creation of sodium facilitates the formation of a non-stop glassy phase for the duration of firing. This glass section correctly fills microvoids, substantially decreasing porosity and proscribing pathways for water absorption. Advanced imaging techniques, such as scanning electron microscopy (SEM), monitor an interconnected glassy network surrounding crystalline grains, resulting in bulk densities exceeding 2.3 g/cm³. This tightly packed microstructure gives sodiceram wonderful resistance to put on, impact, staining, and environmental strain.

Balancing Sodium Content: Limits and Considerations

While sodium is essential for reinforcing vitrification, its attention has to be cautiously controlled. Excessive sodium can cause thermal expansion, probably inflicting warping or glaze mismatch. Typically, producers preserve sodium content material between three–7% with the aid of weight, balanced with feldspar, quartz, and alumina to optimize performance. Overuse of flux agents also can compromise mechanical power, making unique formula and managed firing schedules crucial for retaining sodiceram’s balance and durability.

Key Performance Advantages of Sodiceram

Sodiceram represents a chief soar forward in ceramic generation, combining sturdiness, chemical resistance, and mechanical electricity. It fills the overall performance gap between standard porcelain and advanced technical ceramics, making it a really perfect choice for each architectural and industrial package.

Exceptional Thermal Shock Resistance

One of sodiceram’s maximum extremely good strengths is its ability to face up to rapid temperature changes. Thanks to a cautiously managed coefficient of thermal growth (6–8 ×10⁻⁶ /K), sodiceram can tolerate surprising temperature swings of as much as two hundred °C with out cracking. This makes it extraordinarily appropriate for environments which include professional kitchens, laboratories, or outdoor façades exposed to hot temperature fluctuations.

Superior Chemical Resistance

Sodiceram demonstrates exceptional resilience against chemical exposure. It resists acidic cleaning sellers, slight alkalis, and unusual family chemical substances without etching or degrading. Unlike marble, it does not go through surface damage from acidic materials, and its low porosity prevents absorption of aggressive chemical substances. In commercial settings, sodiceram continues stability while exposed to dilute sulfuric acid or sodium hydroxide, providing a secure, lengthy-lasting fabric answer.

Outstanding Mechanical Strength

Mechanically, sodiceram is constructed to endure high stress. With a Mohs hardness of 7 and abrasion resistance rated above PEI Class V, it withstands heavy foot site visitors, scratching, and put on. Flexural power exceeds 40 MPa, and its impact resistance surpasses traditional porcelain, making it appropriate for excessive-traffic regions along with airports, purchasing centers, and industrial workshops.

Limitations and Best Practices

Despite its robustness, sodiceram continues to be a ceramic material and keeps inherent brittleness compared to metals. Excessive point hundreds or sharp influences can cause localized fractures. Additionally, incorrect set up along with choppy adhesive application or choppy substrates can enlarge pressure and lead to cracks. When set up efficiently, but, sodiceram gives a service lifestyle exceeding 50 years, combining strength, aesthetic enchantment, and lengthy-time period reliability.

Applications Where Sodiceram Excels

Sodiceram is a tremendously versatile ceramic cloth, bridging functionality and layout. Its precise aggregate of sturdiness, chemical resistance, and aesthetic adaptability makes it appropriate for residential, industrial, commercial, inventive, and architectural packages.

Residential Applications

In homes, sodiceram is increasingly favored for floors, wall cladding, countertops, and backsplashes. Its low porosity guarantees water resistance, helping kitchens and lavatories continue to be loose from mould and stains. High scratch resistance makes it ideal for heavy-use areas, even as its aesthetic flexibility lets in finishes starting from herbal wood-like planks to marble-inspired slabs. Whether used in present day or conventional interiors, sodiceram combines practicality with fashion.

Commercial and Industrial Use

High-traffic environments which include airports, hospitals, shopping centers, and workplace buildings benefit from sodiceram’s mechanical power and abrasion resistance. Industrial programs consist of laboratories, cleanrooms, and chemical processing centers, in which the fabric’s resistance to acids, alkalis, and thermal shocks is critical. Its ability to tolerate surprising temperature adjustments makes it well-suited for meals processing flowers and commercial kitchens.

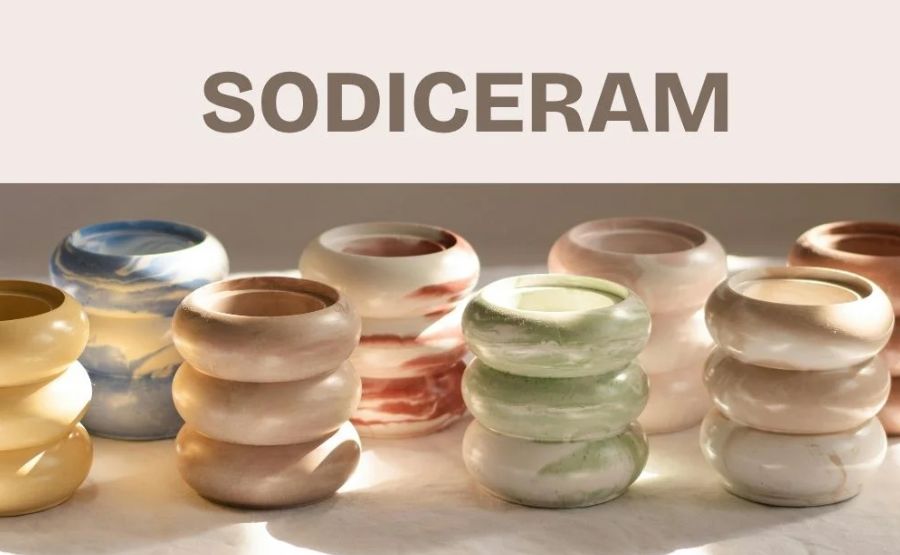

Artistic and Decorative Applications

Sodiceram additionally offers exquisite versatility for creative and decorative projects. Designers and artists can observe virtual printing, steel lusters, or sculptural techniques to create problematic patterns and bespoke surfaces. It is increasingly more utilized in decorative wall panels, façades, and custom installations, where aesthetic attraction needs to be paired with lengthy-term sturdiness—even in outside settings.

Architectural Façades and Cladding

For structure, sodiceram is a sensible yet fashionable answer for curtain partitions, ventilated façades, and excessive-rise cladding structures. It provides UV resistance, frost sturdiness, and low renovation, while its favorable weight-to-power ratio permits for taller, lighter constructing envelopes as compared to natural stone. This makes it a preferred desire for current buildings requiring both overall performance and visual effect.

Manufacturing and Material Processing

Sodiceram’s production combines conventional ceramic strategies with specific manipulation of sodium-based totally completely additives, which might be essential for its superior houses.

Raw Materials:

Typical sodiceram compositions embody kaolin clay, quartz, feldspar, alumina, and sodium-based total fluxes together with sodium carbonate or nepheline syenite. Feldspar additives silica and alumina for vitrification, while sodium compounds decorate the glass phase formation.

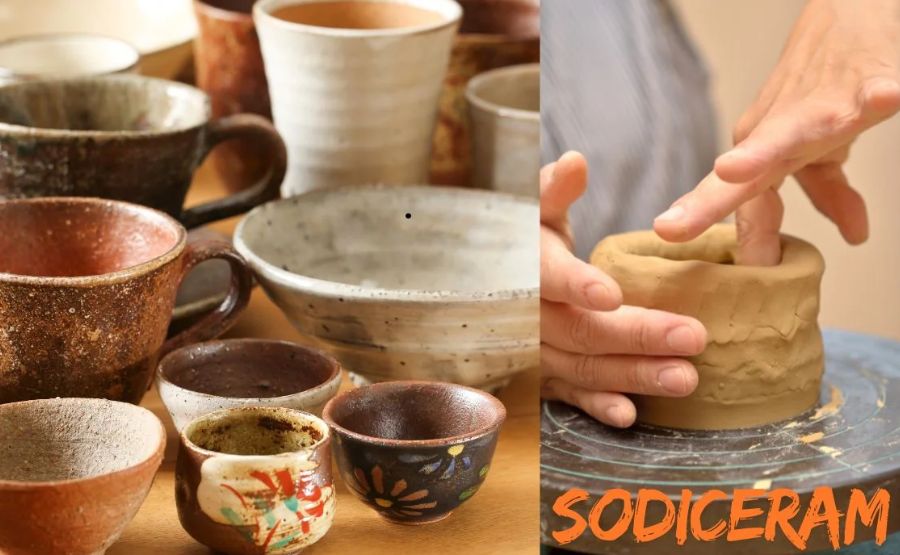

Mixing, Forming, Drying, and Firing:

The raw mixture is homogenized thru ball milling, then spray-dried into super granules. These granules are pressed into tiles or slabs through uniaxial or isostatic urges. After moisture removal in the course of drying, the portions are fired at 1150–1250 °C, allowing sodium to sell vitrification and create a dense, low-porosity microstructure.

Glazing and Surface Finishing:

Sodiceram allows matte, clean, and apparent glazes, executed thru spraying or virtual printing. Sodium-borosilicate frits frequently beautify glaze adhesion, and mechanical sharpening can produce mirror-like surfaces much like engineered stone.

Critical Process Controls:

Consistency is based totally mostly on particle duration distribution, specific sodium content fabric, and correct kiln firing profiles. Deviations can cause warping, glaze defects, or structural inconsistencies. Manufacturers frequently rent XRD (X-ray diffraction) and SEM (scanning electron microscopy) to verify segment formation and microstructural integrity.

How to Specify, Design, and Install Sodiceram Surfaces

For sodiceram to supply its whole performance capability, right specification, format, and installation are essential. Architects, designers, and contractors should adhere to enterprise pleasant practices from material desire through to the very last installation.

Selection Criteria for Architects and Interior Designers

When specifying sodiceram, several key factors have an impact on performance and aesthetics:

- Finish and Color: Choose from matte, smooth, or textured finishes to healthy layout requirements.

- Tile Thickness: Ensures structural integrity and supports mechanical hundreds.

- Slip Resistance: Measured constant with DIN 51130 requirements, important for flooring in moist or excessive-website online visitors areas.

- Mechanical Load Capacity: Important for industrial or commercial enterprise programs.

- Façade Applications: Frost resistance and compatibility with anchoring structures are critical.

- Kitchens and Wet Areas: Chemical resistance and stain prevention manual fabric choice for prolonged-time period durability.

Substrate, Adhesives, and Joint Preparation

Successful sodiceram setup requires a flat, stable substrate with compressive power above 1.5 N/mm². Adhesives should be bendy cementitious sorts (C2TES1 in keeping with EN 12004) to address thermal increase and structural movement. Expansion joints, typically placed each 5 meters, are essential to save you cracking and make certain long-time periods of everyday performance.

Quality Checks and Installation Tolerances

Ensuring precision within the direction of set up is crucial:

- Tile Flatness: Should be inside ±0.5 mm for big-layout tiles.

- Edge Straightness: Guarantees seamless alignment.

- Color Consistency: Maintains aesthetic uniformity during the floor.

- Adhesive Coverage: Must exceed 90% for correct bonding.

- Grouting: In chemical or excessive-moisture environments, epoxy-primarily based completely grouts are encouraged to ensure resistance and sturdiness.

Maintenance, Repairs, and Replacement

Sodiceram surfaces are low-protection in comparison to natural stone or conventional ceramics:

- Cleaning: Neutral detergents are enough; no sealing is wanted.

- Minor Damage: Small chips can be repaired by the usage of shade-matched epoxy fillers.

- Cracks or Severe Damage: Damaged tiles have to be cautiously eliminated and modified to keep ground integrity.

- Routine Care: Regular inspection and cleaning lengthen issuer existence whilst maintaining aesthetic quality.

Sodiceram Cost Structure and Market Overview

Sodiceram occupies a completely unique position inside the ceramics market, combining high overall performance with lengthy-time period cost. While its preliminary purchase price is higher than standard porcelain, its durability, chemical resistance, and occasional protection requirements frequently make it a more cost-powerful alternative over the product’s lifecycle.

Manufacturing Costs

The manufacturing of sodiceram entails numerous key value additives:

- Raw Materials: Includes kaolin clay, feldspar, alumina, quartz, and sodium-based compounds. Sodium components barely boom fabric charges but are critical for better vitrification and overall performance.

- Energy Inputs: Firing in kilns is necessary, but sodiceram’s lower firing temperatures (as compared to traditional porcelain) lessen power consumption by means of about 5–10%.

- Waste Management: Handling of production by means of-merchandise and nice control strategies also contributes to universal manufacturing fees.

Despite those fees, the strength savings and performance in production assist balance the marginally higher uncooked fabric prices.

Price Comparison with Other Materials

Sodiceram is located as a top class mid-tier material, offering overall performance advantages over conventional ceramics and porcelain while last greater lower priced than engineered stone or quartz. Typical marketplace pricing is as follows:

| Material | Approximate Cost (per m²) |

| Standard Ceramic Tile | $10–$20 |

| Porcelain Tile | $20–$40 |

| Engineered Stone (Quartz/Marble) | $60–$120 |

| Sodiceram | $35–$70 |

This pricing displays sodiceram’s stability of first-rate, durability, and aesthetic versatility, making it an attractive choice for architects, indoors designers, and developers in search of a long-lasting answer.

Supplier Margins and Market Premiums

Manufacturers and types frequently position sodiceram at a 20–30% top class over porcelain, emphasizing its superior technical overall performance, sustainability, and layout flexibility. The top class is normally justified by way of the extended carrier lifestyles, decrease upkeep necessities, and resistance to put on, chemical publicity, and thermal shocks, which together offer enormous lengthy-time period value for both residential and industrial tasks.

Sustainability and Lifecycle Considerations for Sodiceram

Sodiceram is designed with sustainability in mind, making it a robust choice for environmentally aware constructing duties. Its low environmental impact, prolonged provider lifestyles, and recyclability align with modern inexperienced building targets, offering blessings over herbal stone and high-energy ceramics.

Energy Efficiency in Manufacturing

A key sustainability characteristic of sodiceram is its reduced firing temperature, finished via sodium fluxing. By reducing kiln temperatures through manner of up to 100 °C, power intake is appreciably decreased compared to standard ceramics and porcelain. Additionally, advanced factories regularly use closed-loop water systems, in addition minimizing water usage and environmental footprint in the course of manufacturing.

Recyclability and End-of-Life Options

Sodiceram can be recycled at the give up of its provider lifestyles. It may be beaten and repurposed as a combination in concrete, road bases, or production fill. Ongoing research explores re-firing waste material as a feedstock for brand new ceramic batches, supporting a closed-loop spherical monetary device and lowering widespread fabric waste.

Certifications and Green Building Credits

Sodiceram supports various sustainable building certifications. Its durability, low VOC emissions, and accountable sourcing allow tasks to earn credits underneath LEED, BREEAM, and WELL rating systems. Using sodiceram can assist architects and developers meet stringent environmental and fitness requirements even as maintaining excessive design first-class.

Embodied Carbon and Lifecycle Impact

The embodied carbon of sodiceram is about 15–20% decrease than conventional porcelain, in particular due to reduced electricity necessities throughout firing. When considering a service lifestyle exceeding 50 years, sodiceram’s carbon footprint per 12 months of use is the lowest of all available floor materials. Its combination of durability, power efficiency, and recyclability positions it as a sustainable, lengthy-term fabric choice for each residential and industrial program.

Competitors and Alternative Technologies to Sodiceram

Sodiceram occupies a unique role within the materials market, bridging the gap between conventional ceramics, herbal stone, and high-performance engineered surfaces. Understanding its competition facilitates architects, designers, and builders to make informed material selections.

Comparison with Porcelain, Vitrified Tile, and Sintered Stone

- Porcelain: While porcelain is broadly used because of its lower cost, it normally reveals higher porosity and lower chemical resistance compared to sodiceram. Sodiceram’s sodium-better vitrification affords superior density and durability, mainly in wet or chemically energetic environments.

- Vitrified Tile: Vitrified tiles are a better opportunity, providing advanced hardness and wear resistance. However, they lack the sodium-precipitated glass segment that gives sodiceram its precise combination of low porosity and thermal stability.

- Sintered Stone: Sintered stone is enormously sturdy and distinctly durable however comes at a significantly better rate factor. Sodiceram provides comparable performance in terms of wear resistance, chemical stability, and aesthetic versatility at a more handy value, making it an attractive choice for mid- to high-give-up tasks.

Comparison with Advanced, Nano, and Smart Ceramics

Nanoceramics: Incorporating nanoscale additives can enhance scratch resistance and antimicrobial homes, but those blessings frequently include extensively higher charges.

Smart Ceramics: Ceramics integrated with sensors or different smart functionalities constitute a modern-day era. Research is ongoing to explore whether or not sodiceram can aid such improvements. For now, sodiceram provides an ultimate balance between affordability, mechanical overall performance, and aesthetic flexibility without the top class charge of excessive-tech ceramics.

When Conventional Materials May Be Preferable

There are scenarios in which conventional ceramics or superior excessive-tech ceramics can also outperform sodiceram:

Budget-Constrained Projects: Standard ceramics continue to be the maximum fee-powerful solution for low-price range packages.

Extreme Technical Requirements: In sectors along with aerospace, defense, or specialised industrial makes use of, ultra-high-performance ceramics with extreme thermal, mechanical, or chemical specifications can also outperform sodiceram.

Overall, sodiceram excels in architectural, indoors layout, and commercial programs, providing a balanced mix of sturdiness, aesthetics, and price-efficiency, at the same time as superior technical ceramics dominate in specialized, excessive-tech fields.

Future Innovations and Research Directions for Sodiceram

Sodiceram continues to conform as studies and technology push the boundaries of ceramic materials. Its combination of durability, low porosity, and aesthetic versatility makes it a sturdy candidate for next-technology packages in shape, design, and business makes use of.

Integration of Sensors and Smart Surface Functions

Emerging studies is exploring the opportunity of embedding piezoelectric sensors, heating factors, or IoT-enabled tracking chips immediately internal sodiceram tiles. This innovation has to allow clever floors structures, self-tracking façades, and interactive surfaces, offering both useful intelligence and long-time durability.

Development of Lighter, Thinner, and More Flexible Panels

Advances in urgent and forming generation can also permit for extremely-thin sodiceram panels as slim as three mm, appropriate for lightweight façade cladding. In addition, hybrid composite formulations should reduce brittleness, growing semi-flexible panels that hold structural energy whilst expanding the opportunities for curved or irregular architectural surfaces.

Additive Manufacturing and 3-D Printing Applications

Ceramic three-D printing techniques are starting new opportunities for sodiceram. By controlling the sodium content material throughout published layers, manufacturers can tailor density and microstructure to create useful gradients. This enables the manufacturing of custom architectural components, elaborate decorative elements, and specialized scientific or commercial ceramics, combining excessive overall performance with design freedom.

Market Trends Driving Sodiceram Adoption

Global tendencies are probable to boost up sodiceram utilization across a couple of areas:

- Sustainable Construction: Increasing recognition of green, lengthy-lasting materials in Europe and Asia.

- Urbanization: Rapid infrastructure growth in India and other emerging markets.

- Façade Regulations: Stricter building codes within the Middle East prefer durable, hearth-resistant, and occasional-renovation cladding.

- Regional Supply Chains: Local availability of sodium feldspars and other key uncooked materials supports value-effective manufacturing and market enlargement.

As these traits converge, sodiceram is positioned not most effective as an excessive-overall performance cloth for current architectural and industrial packages however also as a platform for modern clever surfaces, light-weight panels, and custom designed ceramic answers.

Conclusion

Sodiceram represents a leap forward in the cutting-edge ceramic era, combining strength, low porosity, chemical resistance, and aesthetic versatility. Its revolutionary sodium-primarily based composition promises advanced sturdiness, thermal stability, and design flexibility, making it ideal for residential, commercial, commercial, and architectural packages. Beyond overall performance, sodiceram aligns with sustainability dreams, presenting strength-green production, recyclability, and a discounted carbon footprint over its long carrier life. Positioned between conventional ceramics and superior technical materials, sodiceram provides a balanced answer of affordability, reliability, and layout ability, whilst ongoing studies promises destiny innovations inclusive of clever surfaces, thinner panels, and 3D revealed custom components. In essence, sodiceram ushers in a brand new era of ceramics wherein capability, fashion, and environmental responsibility converge.

FAQs

1. What is Sodiceram and how is it different from traditional ceramics?

Sodiceram is a sophisticated ceramic material with sodium-primarily based compounds. Unlike traditional ceramics, it offers lower porosity, higher durability, advanced chemical resistance, and more aesthetic versatility, making it ideal for both indoor and out of doors applications.

2. What are the main advantages of the usage of Sodiceram?

Sodiceram affords top notch mechanical electricity, thermal surprise resistance, and chemical stability. It also helps various design finishes, reduces preservation needs, and aligns with sustainability desires through power-efficient manufacturing and recyclability.

3. Can Sodiceram be used for residential, business, and industrial programs?

Yes. Sodiceram is fantastically flexible:

- Residential: Flooring, wall cladding, counter tops, backsplashes

- Commercial: Airports, hospitals, buying facilities, places of work

- Industrial: Laboratories, cleanrooms, chemical processing, commercial kitchens

4. Is Sodiceram environmentally friendly and sustainable?

Absolutely. Its decreased firing temperatures store strength, and its lengthy service existence reduces alternative desires. Sodiceram can also be recycled on the crest of its lifestyles and contributes to certifications like LEED, BREEAM, and WELL.

5. Are there any limitations or precautions when using Sodiceram?

While tremendously long lasting, Sodiceram continues to be a ceramic and can be brittle below excessive point loads or sharp influences. Proper installation, substrate training, and enlargement joints are critical to save you cracking and make certain lengthy-term performance.

Read more about Blog At Idiomsinsider

Post Comment